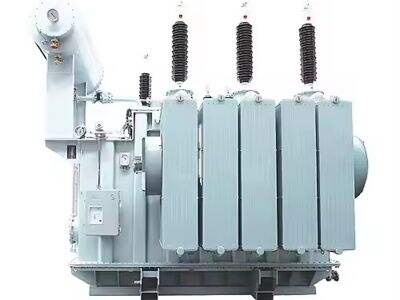

Oil transformers are key to keeping electricity flowing smoothly. They contain special oil to keep their parts from getting damaged and overheated. But the temperature in their surroundings, known as ambient temperature, can affect how well these transformers function. If the air is too hot or too cold, it affects the oil and how well the transformer can do its work. It’s a simple thing, listening to, responding to one of the most basic ought-to-know ambient temperature Dingxin Electricaked we would make about components in an electrical circuit. Here’s more on why that is and what can be done

How ambient temperature influence efficiency and life of oil transformer

As the air surrounding an oil transformer becomes warmer, so does the oil inside of it. That means the oil fails to cool the transformer parts as thoroughly as it should. It helps take away heat from the metal coils and other parts of the transformer. If the oil is too hot, it does not work as quickly or effectively. That causes the transformer to have to struggle harder to keep electricity flowing, and it becomes less efficient. Picture yourself racing on a hot day while wearing a heavy coat, your body gets hotter and you slow down. The transformer is much like us, too, when hot air outside heats up the oil. Beyond slower performance, the heat accelerates the ageing of oil and parts within. The oil could degrade prematurely, losing its ability to insulate and protect the transformer. The metal parts can weaken or wear prematurely, diminishing a transformer’s life. At Dingxin Electric, we operate a number of transformers that winter problems because they run hot without proper cooling. In other cases, the injury is not immediately apparent but becomes evident months or years later. That’s why gaining temperature intelligence in and around the transformer is critical. If the temperature around a transformer remains too high for too long, it can drastically reduce the lifespan of its insulation and lead to repair or replacement far earlier than expected. But if the temperature is managed, the transformer is constructed to withstand heat or both, it can operate for a really long time efficiently. We have found that even small differences in ambient temperature can result in significant changes to the performance and life times of these devices

Typical Impacts of Ambient Temperature of Transformer Oil and Countermeasures

Oil transformers can run into all sorts of issues if they are exposed to high ambient temperature and it might be a headache trying to fix them. Common causes include the oil being too hot, diminishing its insulating power. When insulation is defective, electricity can leak inside the transformer and produce short circuits, perhaps even fires. This is dangerous and costly. Other problem is an increased size or deformation of the internal parts in a heat stressed transformer. Hot metal parts expand and, in some cases, don’t return to their original shape. Such damage might cause programs to malfunction or otherwise compromise the performance of a transformer. Overheating also accelerates chemical reactions within the oil, generating gases that increase pressure inside the tank of a transformer. Pressure that gets too high can lead to leaks and tank damage. To deal with these issues, Dingxin Electric proposes a series of steps. First, cooling systems such as fans or radiators will keep the temperature of the oil and transformer parts lower. Some rigs have oil pumps that move the oil more quickly, helping carry heat away more rapidly. Second, transformers positioned in shaded location or inside buildings are less affected by the sunlight heat radiation. Thirdly, it is possible to use oils that are more resistant to heat which can enable a transformer to withstand higher temperatures as the oil will not degrade. We also advise periodic inspection of the oil temperature and coolant quality. In this way, issues can be detected early on before they have caused significant harm. At times its necessary to redesign the transformer for hotter conditions. From Dingxin Electric, we merge our expertise to develop solutions which meet the unique environment of every customer. We know because each transformer is subjected to its unique challenges depending on the location it operates at

The Importance of Ambient Temperature for Oil Transformer Wholesale Quality and Reliability

Ambient temperature refers to the temperature of the air surrounding the oil transformer. This is crucial, since oil transformers must be kept cool in order to operate efficiently. If the air around them becomes too hot, the oil in the transformer can become too warm. This can lead to the transformer wearing out more quickly or not performing as efficiently. When the oil becomes too hot, it can no longer dissipate heat from the metal components inside the transformer. Then the damage will occur in the transformer and they will not work properly. For wholesale purchasers who purchase a lot of oil transformers, it is particularly necessary to understand how the ambient temperature has an impact on these equipments. If transformers are going to be used where temperatures are high they may require extra care or special design considerations in order to keep them cool. If they overheat a lot, their quality and life will decrease, meaning more expenses to fix or replace them. At the Dingxin Electric, we realize that it is always wise to consider the temperature of the day when you are manufacturing and selling oil transformer. We build our transformers to withstand a range of temperatures, so they do not weaken and work for many years. That in turn has enabled our customers to obtain good, reliable transformers that don’t fail easily. In a word, ambient temperature plays a role in how well oil transformers function and how long they last. Wholesale buyers need to look out for this every time they purchase transformers in order to ensure the quality and reliability of the products

Wholesale Purchasers Guide: Ensuring Silent Transformers Work in Variable Climates

Wholesale customers have a big responsibility to ensure the oil transformers they purchase will be efficient no matter where they are used. Different places have different temperatures. Some regions are hot, others cooler. To ensure oil transformers provide proper performance, buyers should consider the environment where they will be employed. One way to accomplish this is by requesting transformers purposely built for a certain temperature. Dingxin Electric provides transformers that can be used in hot and cold climatic conditions. These transformers come with special oil and designs that help them stay cool or warm, as necessary, in any kind of weather. Another way in which buyers can assist, the diners agree, is to promote transformers at good locations. For instance they should not be placed in direct sunlight, or closed off spaces with no air flow. This serves to lower the ambient temperature of the transformer. And, cool systems like fans or air conditioners can help when the weather is extremely hot as well. Second, wholesale buyers should be provided with data about how the transformer will react to heat. Related Product Ranges Dingxin Electric can supply lists of temperature limits and recommended uses. This also makes it easier for buyers to select the so pack transformers they need. By considering the climate and using proper products and installation methods, wholesale buyers can ensure that their oil transformers are working well for many years, even in adverse weather. That’s lower there are fewer issues and better performance in all sorts of beach types

The Benefits of Ambient Temperature Control in Oil Cooled Transformers

Maintaining ambient temperature is one of the most effective methods for making oil transformers have a longer life and better work. If the air temperature around a transformer remains constant and not too hot, the oil inside can cool its parts effectively. This prevents the transformer from wearing out prematurely. If too high, the oil can break down more quickly and the metal parts may start to wear out. This causes the transformer to fail earlier than it should. We at Dingxin Electric understand just how indispensable it is to manage the transformer’s surrounding temperature. We suggest placing transformers in shaded space, or indoors. Occasionally, adding cooling devices such as fans or specially equipped cooling systems can be more accommodating of lingering thermal excesses. These measures can have an enormous impact on how long a transformer operates effectively. The transformer operates more efficiently when it is temperature controlled, as well. That means less energy is lost, and the transformer remains safer. This way, customers save on repairs and electricity costs. Anywholesale buyers can also use control ambient temperature to increase the value of their transformers, ensuring they will last longer and perform better. Dingxin Electric is committed to supporting its customers with advice and tools to manage ambient temperature to obtain optimum performances from oil type transformers. Preserving that temperature is an easy and effective way to safeguard transformers, and keep them performing at righteous levels for many years

Table of Contents

- How ambient temperature influence efficiency and life of oil transformer

- Typical Impacts of Ambient Temperature of Transformer Oil and Countermeasures

- The Importance of Ambient Temperature for Oil Transformer Wholesale Quality and Reliability

- Wholesale Purchasers Guide: Ensuring Silent Transformers Work in Variable Climates

- The Benefits of Ambient Temperature Control in Oil Cooled Transformers